Horizontal Values Range between 10 Inches and 25 Inches

If the horizontal distance is less than 10 inches (25 cm), then H is set at 10 inches (25 cm). Although objects can be carried or held closer than 10 inches from the ankles, most objects that are closer than this cannot be lifted without interference with the body. The maximum value of H is 25 inches (63 cm). Objects at a distance of more than 25 inches from the ankles normally cannot be lifted vertically without some loss of balance.

Vertical Values Range between 0 and 70 Inches

The vertical location is limited by the floor surface and the upper limit of vertical reach for lifting (i.e. 70 inches or 175 cm). The vertical location should be measured at the origin and the destination of the lift to determine the travel distance (D).

Distance Values Range between 10 Inches and 70 Inches

The variable D is assumed to be at least 10 inches (25 cm), and no greater than 70 inches (175 cm). If the vertical travel distance is less than 10 inches (25 cm), then D should be set at the minimum distance of 10 inches (25 cm).

Asymmetry Values

The angle A is limited to the range from 0° to 135°. If A > 135°, then AM is set equal to zero, which results in a RWL of zero, or no load.

Frequency Value Range

Lifting frequency (F) for repetitive lifting may range from 0.2 lifts/minute to a maximum frequency that is dependent on the vertical location of the object (V) and the duration of lifting. Lifting above the maximum frequency results in a RWL of 0.0, except for discontinuous lifting where the maximum frequency is 15 lifts/minute.

Classification of Gripping Method (Coupling)

The hand-to-object coupling or gripping method (C) affects not only the maximum force a worker can or must exert on the object, but also the vertical location of the hands during the lift. A good coupling will reduce the maximum grasp forces required and increase the acceptable weight for lifting, while a poor coupling will generally require higher maximum grasp forces and decrease the acceptable weight for lifting. The entire range of the lift should be considered when classifying hand-to-object couplings, with classification based on overall effectiveness. The coupling must be classified as good, fair, or poor. If there is any doubt about a particular classification, select the more stressful classification.

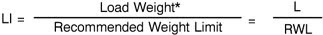

Lifting Index (LI)

The Lifting Index (LI) provides a relative estimate of the physical stress associated with a manual lifting job. The equation for the (LI) is:

How to Use the RWL and LI to Guide Ergonomic Design

The recommended weight limit (RWL) and lifting index (LI) can be used to guide ergonomic design in several ways:

-

The individual multipliers can be used to identify specific job-related problems. The relative magnitude of each multiplier indicates the relative contribution of each task factor (e.g., horizontal, vertical, frequency, etc.).

-

The RWL can be used to guide the redesign of existing manual lifting jobs or to design new manual lifting jobs. For example, if the task variables are fixed, then the maximum weight of the load could be selected so as not to exceed the RWL; if the weight is fixed, then the task variables could be optimized so as not to exceed the RWL.

-

The LI can be used to estimate the relative magnitude of physical stress for a task or job. The greater the LI, the smaller the fraction of workers capable of safely sustaining the level of activity. Thus, two or more job designs could be compared.

-

The LI can be used to prioritize ergonomic redesign. For example, a series of suspected hazardous jobs could be ranked according to the LI and a control strategy could be developed according to the rank ordering (i.e., jobs with lifting indices above 1.0 or higher would benefit the most from redesign).

This Lifting Index can be used to identify potentially hazardous lifting jobs or to compare the relative severity of two jobs for the purpose of evaluating and redesigning them. Lifting tasks with a LI > 1.0 pose an increased risk for lifting-related low back pain for a fraction of the workforce. Therefore, the goal should be to design all lifting jobs to achieve a LI of 1.0 or less.

No comments:

Post a Comment